TORQLOK EPOXY

THREAD LOCKING COMPOUND

TorqLok is recommended for bonding all threaded and sleeve type applications where welding is undesirable.

AVAILABLE PACKAGE

1 Oz = 28 gms & 2 Oz = 56 gms

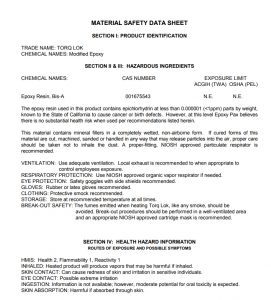

DESCRIPTION TORQ-LOK

TorqLok is an epoxy based metal adhesive. Conveniently packaged in the EPOXY PAX, TorqLok is preformulated to the exact mix ratio, eliminating any weighing or mixing. TorqLok is recommended for bonding all threaded and sleeve type applications where welding is undesirable. This system will withstand break-out torques twice as great as normally recommended make-up torques. TorqLok will withstand continuous vibrations and heavy shock loads. TorqLok is impervious to oil, petroleum solvents, gasoline, alcohols, acids, alkalis and salts. TorqLok also prevents galling of threads.

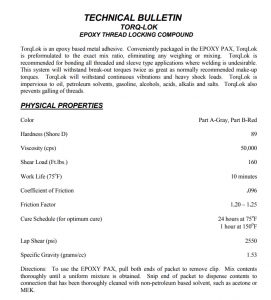

PHYSICAL PROPERTIES

Color – Part A-Gray, Part B-Red

Hardness (Shore D) – 89

Viscosity (cps) – 50,000

Shear Load (Ft.lbs.) – 160

Work Life (75oF) – 10 minutes

Coefficient of Friction – .096

Friction Factor – 1.20 – 1.25

Lap Shear (psi) – 2550

Specific Gravity (grams/cc) – 1.53

Cure Schedule-24 hours at 75 F,1 hour at 150 F